Mold Design Software

In plastic manufacturing, the quality of a product often depends on the mold design. Poor mold design can lead to defects, increased costs, and delays. By using advanced mold design software, like VISI Mold, you can avoid many common design issues. This blog explains five common problems in mold design and how VISI software helps eliminate them.

1. Warpage and Shrinkage

Warpage and shrinkage are frequent injection molding defects. They occur when plastic cools unevenly inside the mold. The result is a distorted or misshaped part.

Solution with VISI Mold: VISI mold software includes tools for mold flow analysis and cooling channel simulation. These tools help designers predict and fix cooling issues early. You can optimize part geometry and mold design before manufacturing.

Why it works:

Simulates material behavior during cooling

Shows possible shrinkage areas

Suggests improvements to cooling system

Result: Accurate parts with reduced rework and waste.

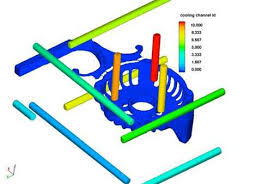

2. Poor Cooling Channel Design

Poor cooling design increases cycle time and affects part quality. Uneven cooling can cause hot spots, cracks, and surface defects.

Solution with VISI Mold: VISI software for mold design offers precise tools to improve cooling channel design. It simulates heat flow and suggests ideal channel placement.

Why it works:

Creates detailed cooling channel models

Tests various cooling layouts

Ensures even temperature distribution

Result: Faster cycle times and better part finish.

3. Inaccurate Core and Cavity Design

Core and cavity design errors can cause poor fit, flashing, and incomplete filling. These defects often need mold rework, which adds cost and delays.

Solution with VISI CAD CAM: VISI software automates core and cavity design. It uses the part geometry to generate accurate mold blocks.

Why it works:

Aligns core and cavity perfectly

Supports complex shapes with high accuracy

Includes built-in tolerance controls

Result: Higher accuracy and fewer manual corrections.

4. Lack of Mold Flow Analysis

Without mold flow analysis, you can’t predict how plastic will fill the mold. This can lead to air traps, short shots, or weld lines.

Solution with VISI Mold: VISI Mold includes advanced mold flow analysis features. It shows the behavior of molten plastic inside the mold cavity.

Why it works:

Simulates fill, pack, and cooling stages

Highlights areas of concern like weld lines

Allows changes before tooling starts

Result: Improved part quality and fewer molding issues.

5. Inefficient Design-to-Manufacture Workflow

Manual data transfer between CAD and CAM increases errors. It also slows down the mold making process.

Solution with VISI CAD CAM: VISI provides an integrated 3D mold design solution. Designers and toolmakers can work in a single environment.

Why it works:

Smooth CAD CAM integration

Less rework due to data mismatch

Faster time-to-market

Result: Shorter project times and higher productivity.

Why VISI is the Best Mold Design Software

VISI mold vs other CAD tools for toolmakers shows clear advantages:

Tailored for plastic mold design

Combines CAD CAM for mold making

Offers injection mold design tools with high precision

Ideal software to eliminate warpage and shrinkage in molds

Supports tool and die design with ease

How to Fix Common Mold Design Problems Using VISI

Optimize core and cavity layout

Improve cooling with channel simulation

Predict defects using mold flow tools

Accelerate tool design with integrated modules

Best Software for Plastic Injection Mold Design VISI stands out because it supports every step from design to toolpath. Its accuracy and simulation features make it one of the best options available today.

Conclusion

Using VISI mold software reduces common mold design issues. You get better results, save time, and cut costs. Whether you’re a designer or a toolmaker, VISI software for mold design improves every step.

If you are looking for the best mold design software that solves real-world challenges, contact Corengg Technologies today.