VISI Die Tool Design

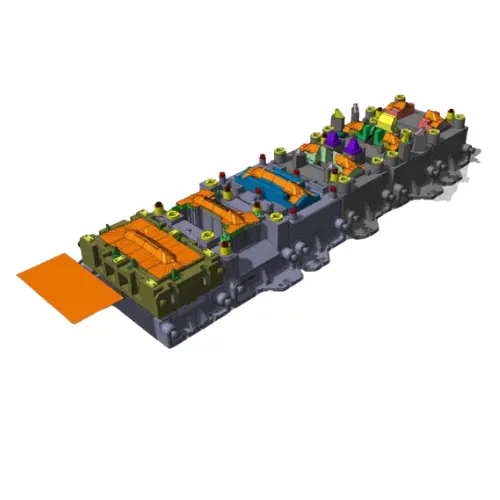

Dedicated solutions for progressive VISI die tool design and press tools

Optimize Your Manufacturing with VISI Die Tool Design and Press Tool Software

Corengg Technologies offers the cutting-edge VISI Die Tool Design and Press Tool Software, a robust solution for enhancing die and press tool design processes. Tailored for precision manufacturing, VISI integrates powerful CAD/CAM capabilities that support every stage of design, from concept to production. Featuring specialized tools for VISI Die Moulding, it ensures high-quality designs, accurate simulations, and efficient tool management. This software reduces production time, minimizes errors, and optimizes workflows, making it the ideal choice for manufacturers looking to improve their design capabilities and manufacturing efficiency.

VISI Die Tool Design and Press tool Software

Corengg Technologies provides VISI Tool Design Software and Press Tool Software, a comprehensive solution for efficient and accurate design of dies, moulds, and press tools. Ideal for tooling professionals, it streamlines the development process with integrated CAD/CAM capabilities and specialized features for VISI Die Moulding, ensuring high precision and faster turnaround times.

Productive and efficient die design

Industry specific functionality provides a more productive and efficient design experience. Helping the designer with intelligent decisions will reduce the potential for error and greatly improve manufacturing productivity.

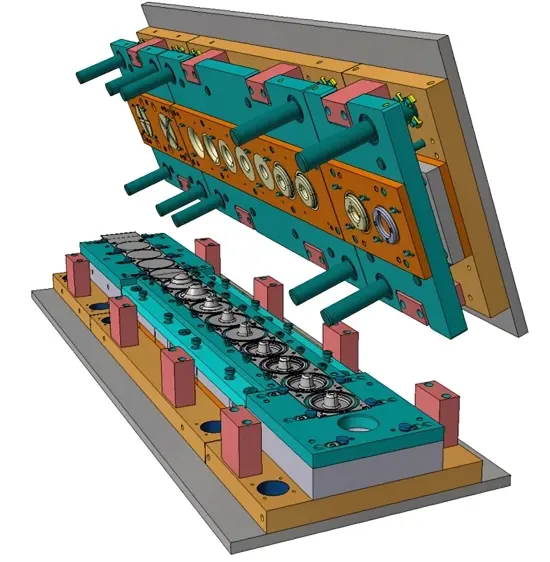

Features at a glance: VISI Die Tool Design

- Variable neutral fibre calculation

- Part analysis and bend study

- Automatic blank development

- ep-by-step unfolding

- 3D strip design and shearing simulation

- Bending and shearing stress calculations

- User-defined tool templates

- Parametric component libraries

- Automatic link to plate manufacture

- Associative tool detailing

CAD and modelling tools

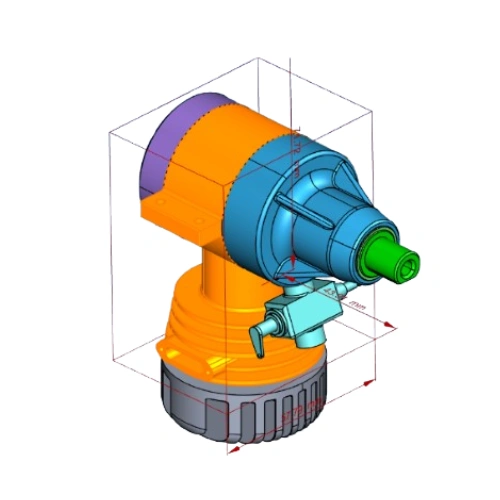

VISI can work directly with Parasolid, IGES, CATIA, Creo, UG-NX, STEP, Solid Works, Solid Edge, Inventor, ACIS, DXF, DWG, JT Open, STL and VDA files. The extensive range of translators ensures that users can work with data from almost any supplier. The ability to skip corrupt records during the import process provides a platform from where the most inconsistent data can be managed. Very large files can be handled with ease and companies working with complex designs will benefit from the ease with which their customer’s CAD data can be manipulated.

VISI Die Tool Design requires a robust CAD, adequate RAM, a compatible operating system, and software for simulation design efficiency.

Effective support for VISI Die Tool includes training, user manuals, and reliable technical assistance to ensure tool design and operation.

Smart design and manufacturing workflow solutions for plastic injection moulds and progressive dies.

VISI Software case studies highlight design solutions, improved efficiency and precision in manufacturing processes across diverse industries.